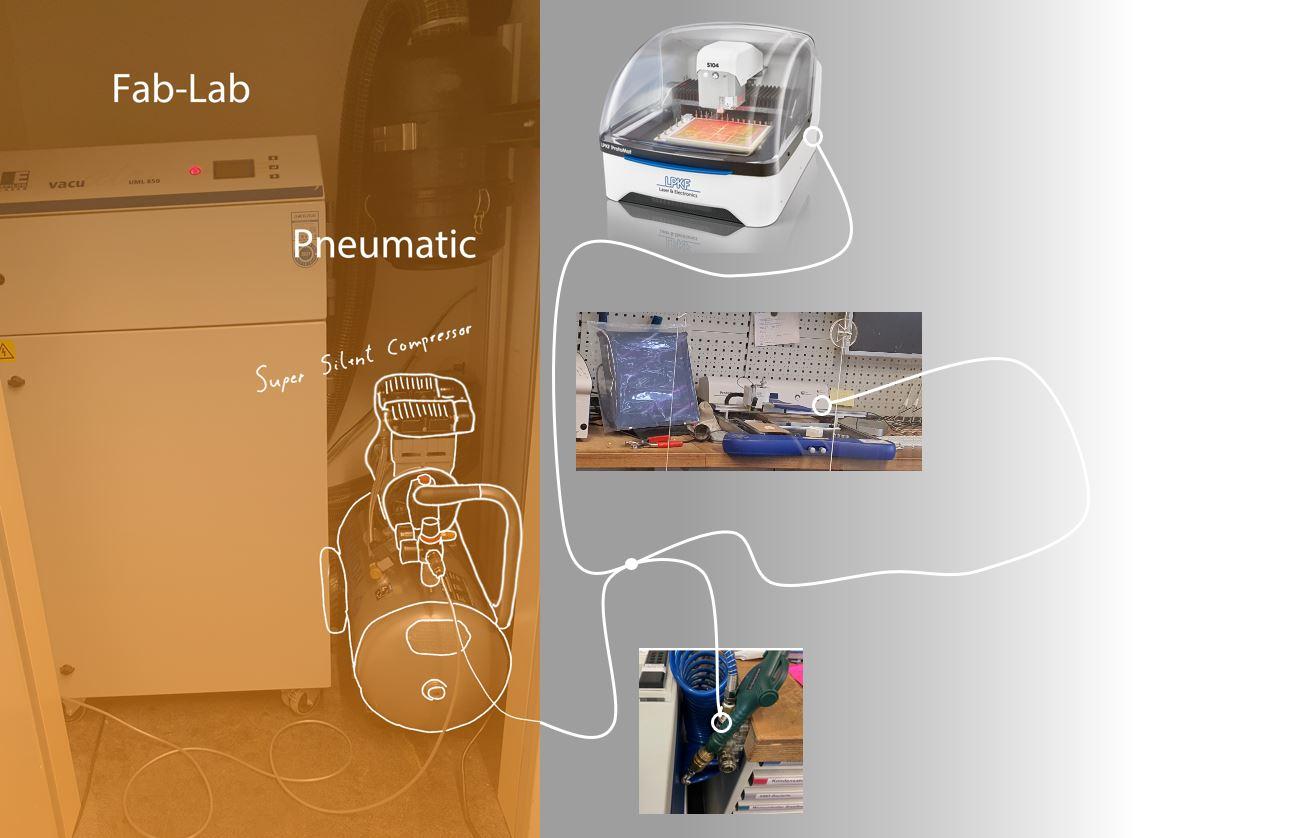

The Fablab Pneumatic

... starts in the Compressor

As for the Compressor we use a Hyundai Super Silent SAC55753 which is a silent and powerfull small

compressor unit at the same time. Technical facts: 1.5kW, 8bar, 50l, 232 l/min, 59.48 dB(A), 37,4 kg

What is pneumatic good for

The Pneumatic can be used to run compact air powered tools, like air blow guns, spray guns, pneumatic

drives, pneumatic assisted machines (like the pick and place machine, the PCB-Mill etc.

How to operate the compressor

Normally, nothing needs to be done to the compressor in order to just use the compressed air. The compressor

is set up in such a way that it supplies the Fab-Lab with compressed air throughout the day and switches off

automatically when not in use (immediately when the pressure reservoir is full). Only in the mornings and

evenings the main switch has to be switched on/off for safety reasons. The compressed air can be taken from the

respective locations of the compressed air quick couplings (e.g. next to the laser cutter at the workbench) and

the compressed air assisted devices can easily be put into use (e.g. the PCB milling machine, pick and place machine).

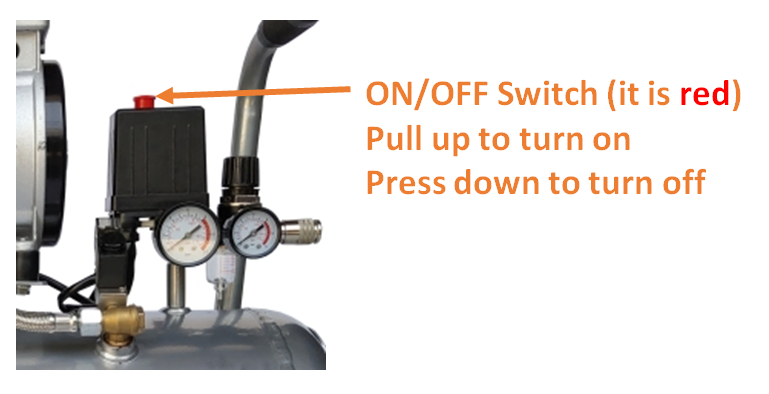

In all other cases, here is how the compressor is operated and maintained

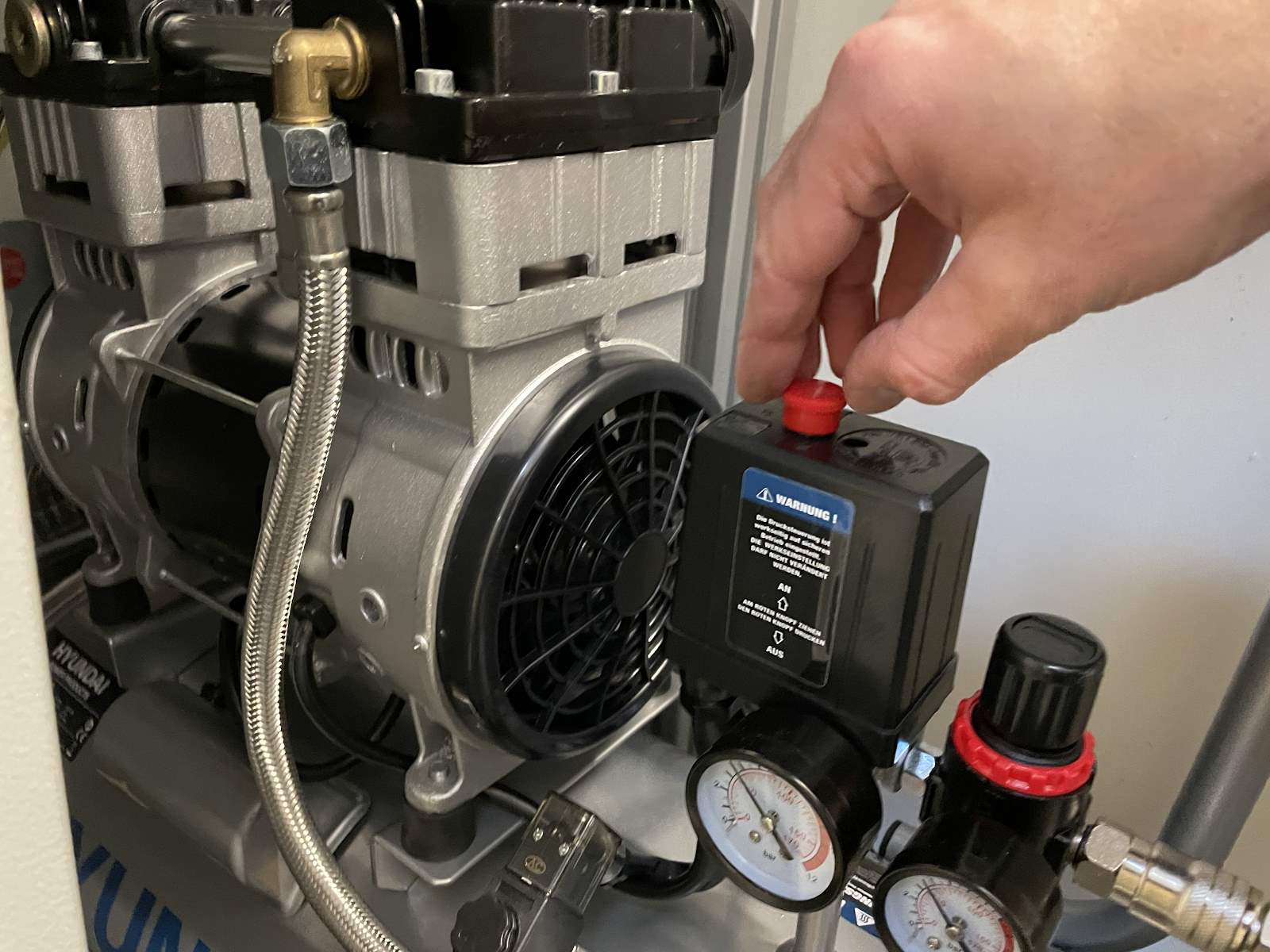

Use the red ON/OFF switch to power the compressor. Pull the knob to start the Compressor, push it

down to turn it off.

The Compressor does not need to be switched off manually in normal operating mode since it uses an

automatic pressure switch, which turns the compressor off if the pressure limit has reached (at around 7-8 bar).

Pull the switch up to

↑power ON the compressor

Press the switch down to manually

↓turn OFF the compressor.

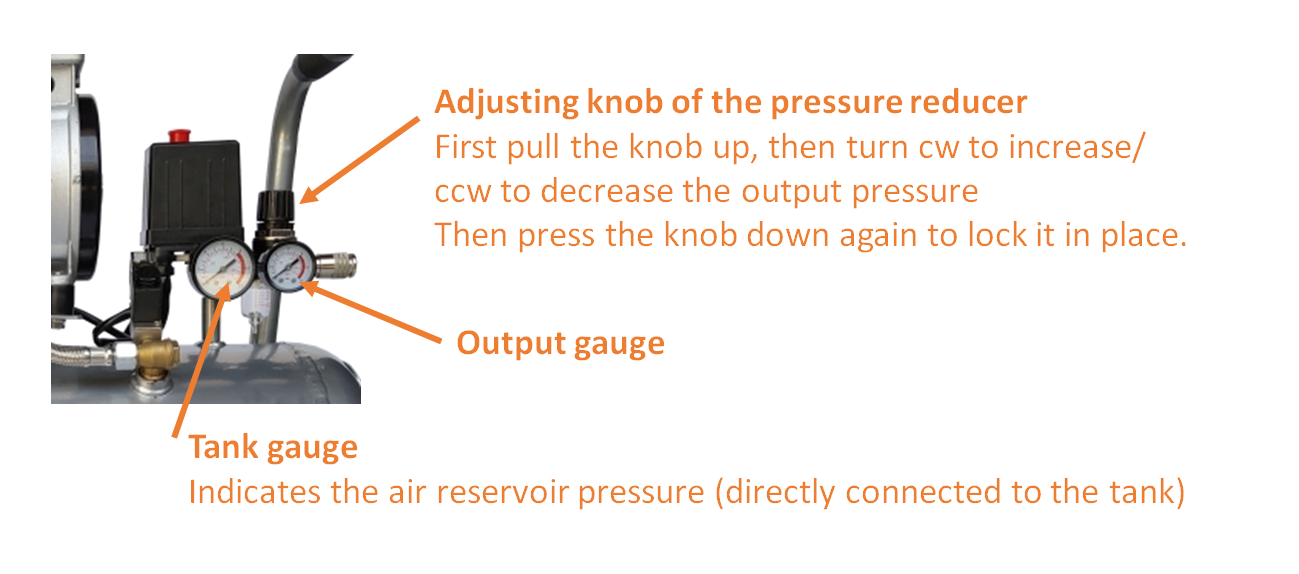

How to use the pressure regulator

In most applications, the pressure reducer does not need to be touched. However, if a certain pressure is still

required, it can then be adjusted in the following way:

First pull the knob up, then turn cw to increase/ccw to decrease the output pressure. Then press the knob

down again to lock it in place. when the pressure is decreased, the pressure gauge may not immediately

indicate the reduction. This is the case when there is still a higher static pressure on the output line.

In this case, it helps to simply reduce the pressure of the line (e.g. via the air gun). Pressure increases are

always indicated immediately.

How to use the pneumatic quick couplings

grab around the plug and insert it into the coupling. Simultaneously press down the quick release ring with

your thumb and forefinger. now release the quick release ring so that the plug is locked in place.

that's it - connected!

If you want to disconnect the coupling, first push down the with your hand embraced plug and then press

down the quick release ring (. now the plug is released and can be pulled out of the coupling. With this method,

the quick release is without tension and can easily be unclamped.

How to maintain the compressor

Safety: Wear hearing protection before doing anything at the compressor! Disconnect the power cord for each maintenance measure! Drain the air through the drain plug before each maintenance measure!

- The air filters should be cleaned once a month and should be changed annually.

To clean it: 1) Unscrew it with the case from the cylinder. 2) Open the case by twisting the two halves. 3) Suck out any dust or dirt with a vacuum cleaner.

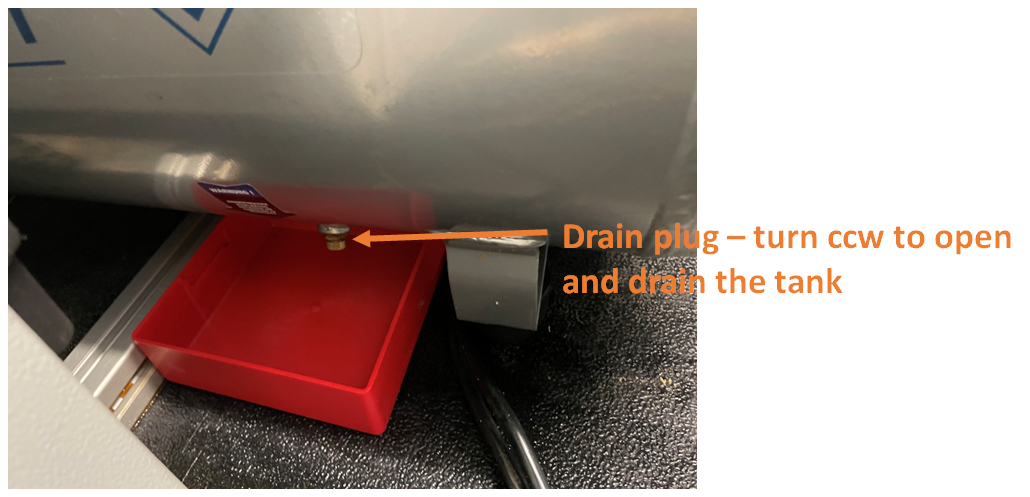

- Condensation water: After each operation (in our case, due to our light use, once a week can be sufficient )

condensed water should be drained off. This serves to protect the pressure vessel against corrosion and

ensures compressed air that does not consist only of water. To do this, open the drain plug under the

pressure tank and drain the water into the collection container (which is normally placed there).

Screw the the drain plug back in.

- keep everything clean! if necessary clean and care the compressor

- If any type of damage or corrosion is detected, the compressor must be taken out of service immediately

and the relevant specialist/manufacturer must be consulted.

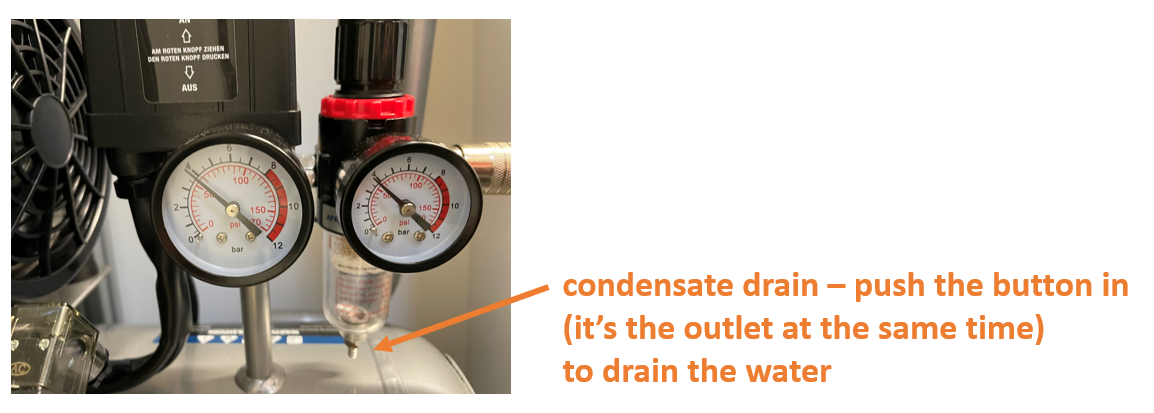

- This device is an additional condensate drain to keep the air supply dry. Turn the pressure with the

pressure reducer down. Press the drain plug upwards from below to simply drain the condensate.

Drain it daily!

Safety precautions

Safety when working with compressed air

- Never direct compressed air at people or animals.

- All connected compressed air equipment, pipelines, hoses and fittings must be designed for at least

the maximum permissible operating pressure or connected via a pressure reducer pressure reducer.

- Compressors and lines reach high temperatures during operation. Contact can lead to injuries.

- The use of the device in a fire sensitive or explosive environment is strictly prohibited.

- The gases or vapors sucked in by the compressor must be free of vapors or gases which could cause fires '

or explosions in the comprThis device is an additional condensate drain to keep the air supply dry. Turn the pressure with the

pressure reducer down. Press the drain plug upwards from below to simply drain the condensate.

Drain it daily!essor.

- Do not spray flammable liquids near sparks, flames, ignition sources. Spray area must be well ventilated.

The compressor should be at least 6 meters from the spraying area. Never smoke while spraying.

- When loosening the hose coupling, hold the coupling piece firmly with your hand, to avoid injuries

caused by the hose recoiling.

- For pressures above 7 bar, the hoses must be connected with a safety cable, e.g. a wire rope.

- The pressure vessel as well as lines and air equipment must be checked regularly for damage and rust.

Defective devices must not be switched on.

- wear safety glasses