Makerbot Frostruder mk2

We have a Makerbot Frostruder mk2. The Frostruder is basically a syringe connected to a pressure source, typically an air compressor. You can use it for frosting extrusion, but it will also work with many other materials like peanut butter, nutella, clay, silicone, epoxy, and dough.In this tutorial, we will show how to use the frostruder with dough.

Connect Frostruder to Makerbot Mainboard

Pressure valve: C- and C+ on the mainboard.Relieve valve: A- and A+ on the mainboard.

What you need:

100g Masa Harina (a corn dough often used for tortillas) - you can buy it at MEX-AL in Aachen.250g water

Preparation

mix the Masa Harina and the water with a stirring staff. I used the Makita and a random tool from my kitchen:

Next, fill the syringe with the dough. For more information, see this wiki page.

I used the following settings:

- 40PSI air pressure

- white needle (gauge 17 - 1.15mm)

- feedrate 5000 mm/min (value for skeinforge: 83)

- 1.7mm layerthickness (for skeinforge)

Creating the G-Code

We want to print this object: a turtleOn the wiki page before, there was a step by step introduction into the frostruder and how to use it with your makerbot. The most important steps are:

- open your STL file in ReplicatorG

- check your skeinforge settings in ReplicatorG (values described on the makerbot frostruder wiki page)

- create gcode with ReplicatorG's skeinforge engine

- save gcode to your harddisk

- use frostforge.py to convert your gcode file to a valid frostruder gcode syntax

- open this modified gcode file into ReplicatorG, find your home position and start printing! (connect the air pressure first and test the valves!)

You can use this gCode file for 1.6mm layer thickness: 1.6mm layer thickness turtle for frostruder - printing time: 27 seconds!

Results

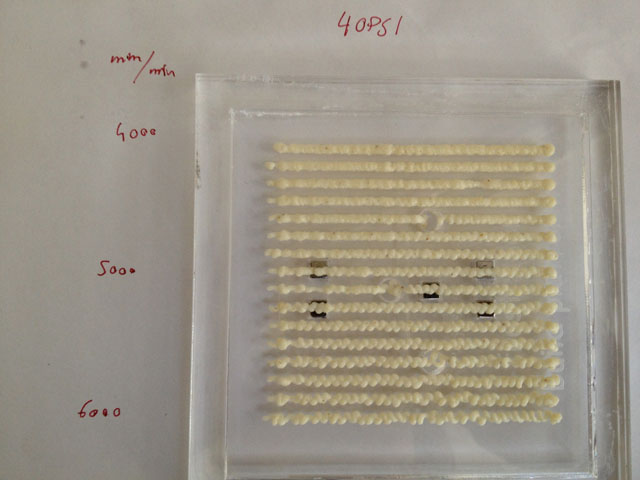

First, I tried to find a good feedrate. This result shows, that 5000 mm/min is a good value:

Then, I tried different values for the layerthickness in skeinforge. In the end, valies between 1.5 and 1.8 looked promising. Here is a turtle, printed with 1.6mm layerthickness:

A short movie clip: (download Link):

After 10 minutes in the oven, the turtle looks like this: