Aachen Maker Meetup #167: Functional Hacks and Model Innovations

Thorsten's Projects:

Thorsten presented a series of test houses for model railroads. The models were designed to be printed entirely without supports, streamlining the printing process and reducing post-processing time — a practical approach for anyone working at scale in model making.

Martin's Projects:

Martin showcased his ongoing efforts to improve filament storage and drying:

-

He experimented with drying silica gel using an air fryer — a quick and accessible solution for recharging desiccants.

-

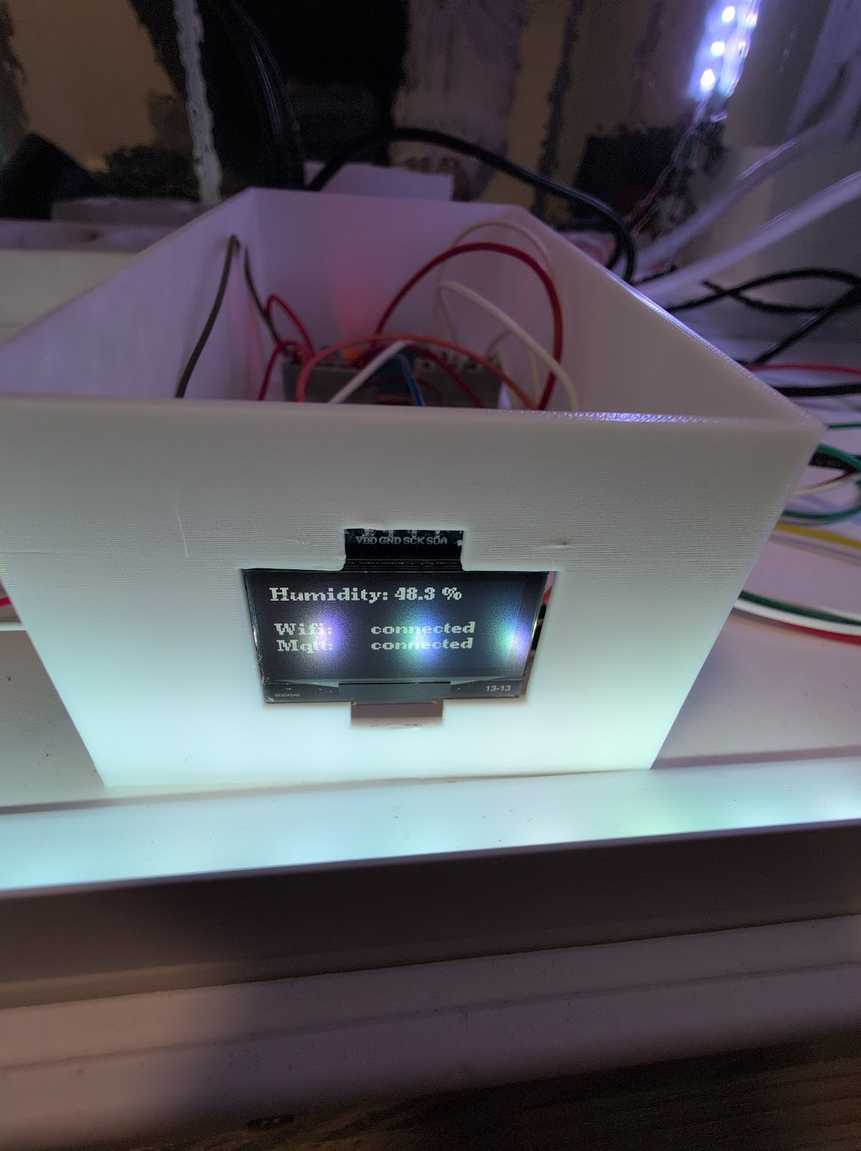

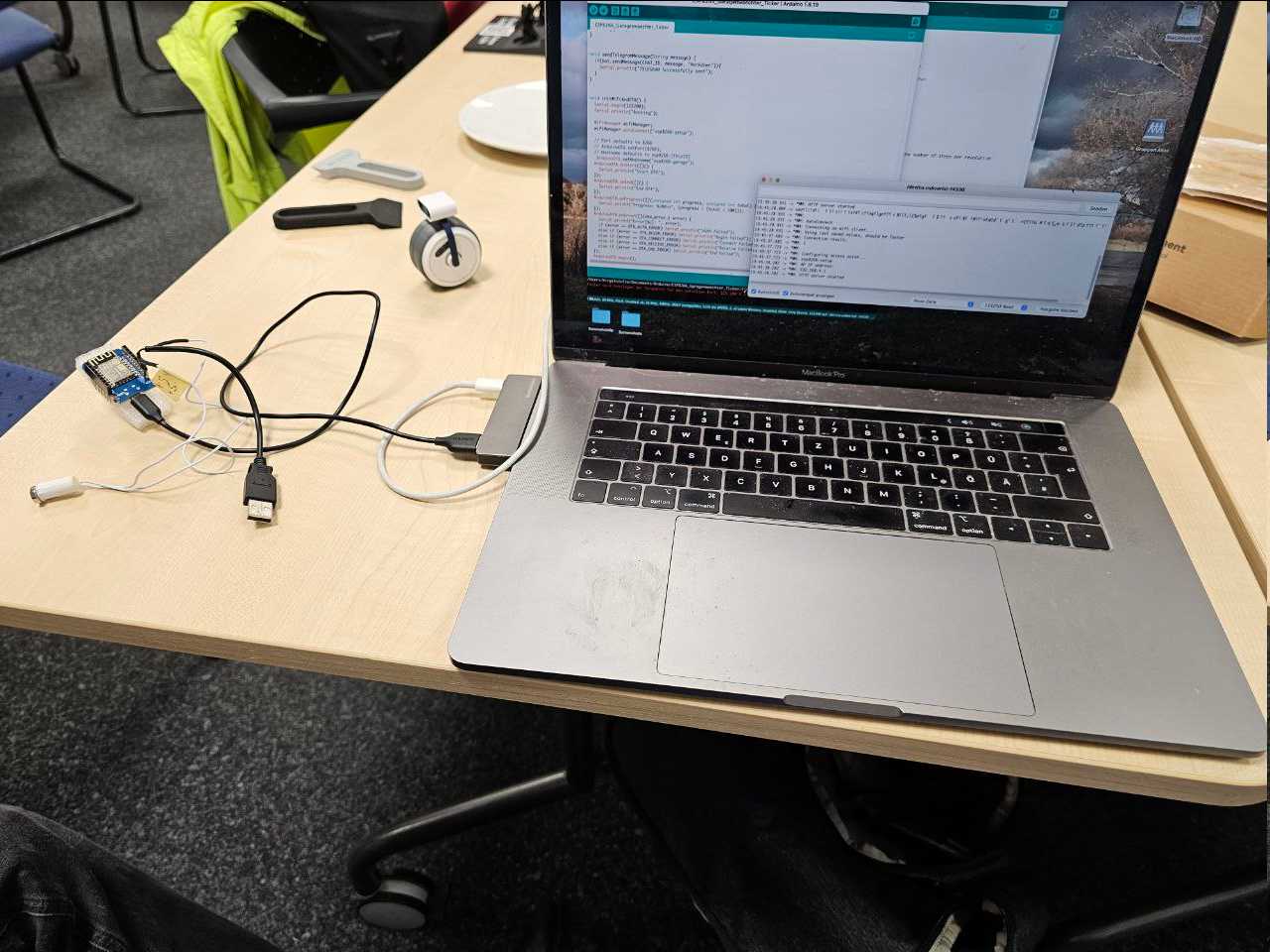

He repurposed an IKEA Billy shelf into a filament drying cabinet. The setup includes LED lighting, a mirrored back wall, and a humidity display driven by an ESP32 microcontroller and a DHT22 sensor, which also logs data using the MQTT protocol.

-

A built-in dehumidifier was initially tested but removed due to poor performance, replaced instead by more reliable silica gel beads.

Levin & Birgit's Project:

Together, Levin and Birgit worked on repairing a garage door opener. They’re modifying the system so it sends email notifications rather than using Telegram bots, making it more robust and flexible for future use.

Birgit's Projects:

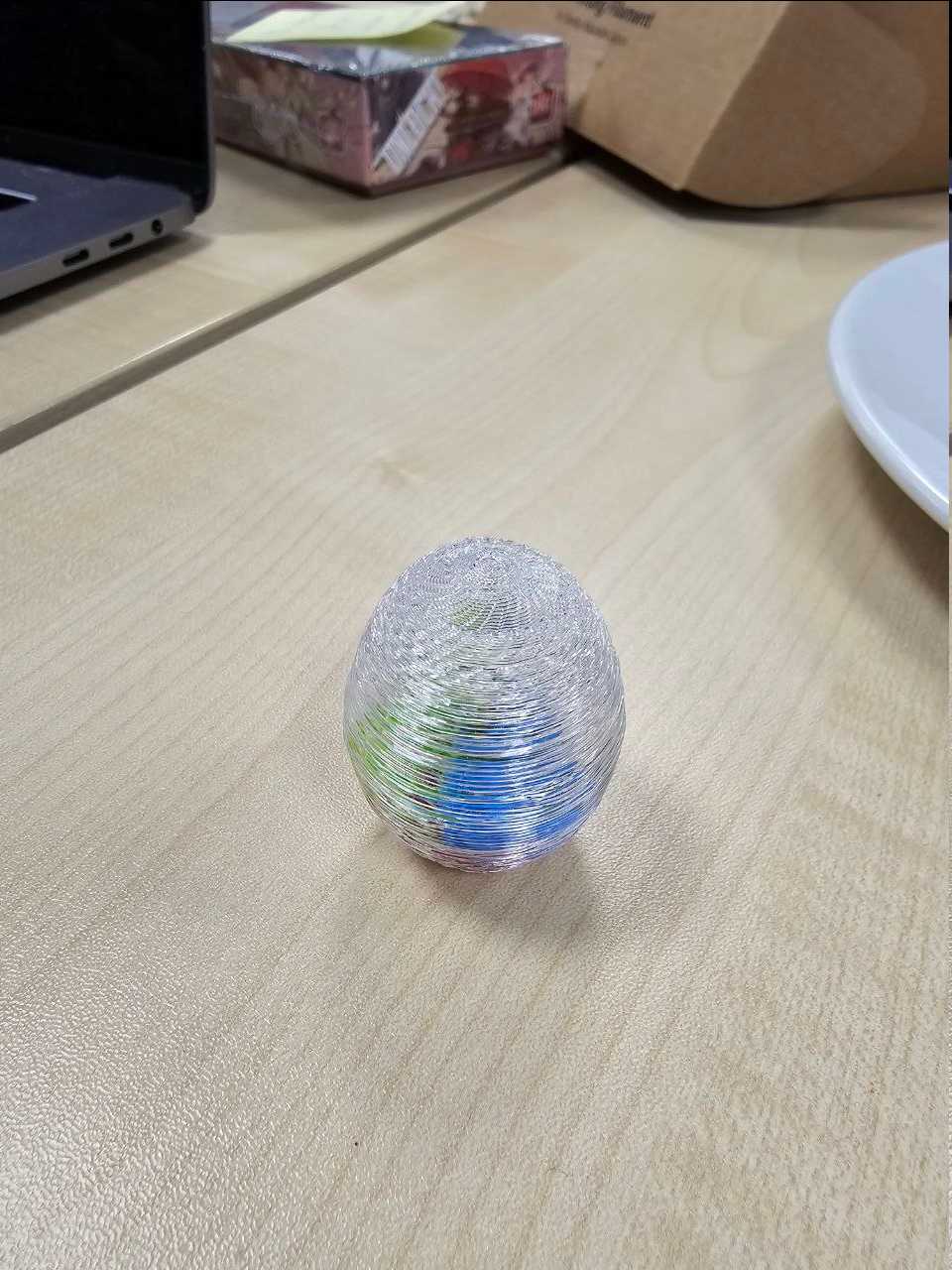

In addition to the collaborative repair project, Birgit brought a playful 3D print: a PETG egg with a core made from filament purge waste — affectionately referred to as “filament poop.” A fun way to recycle and repurpose leftover material.

Helge's Project:

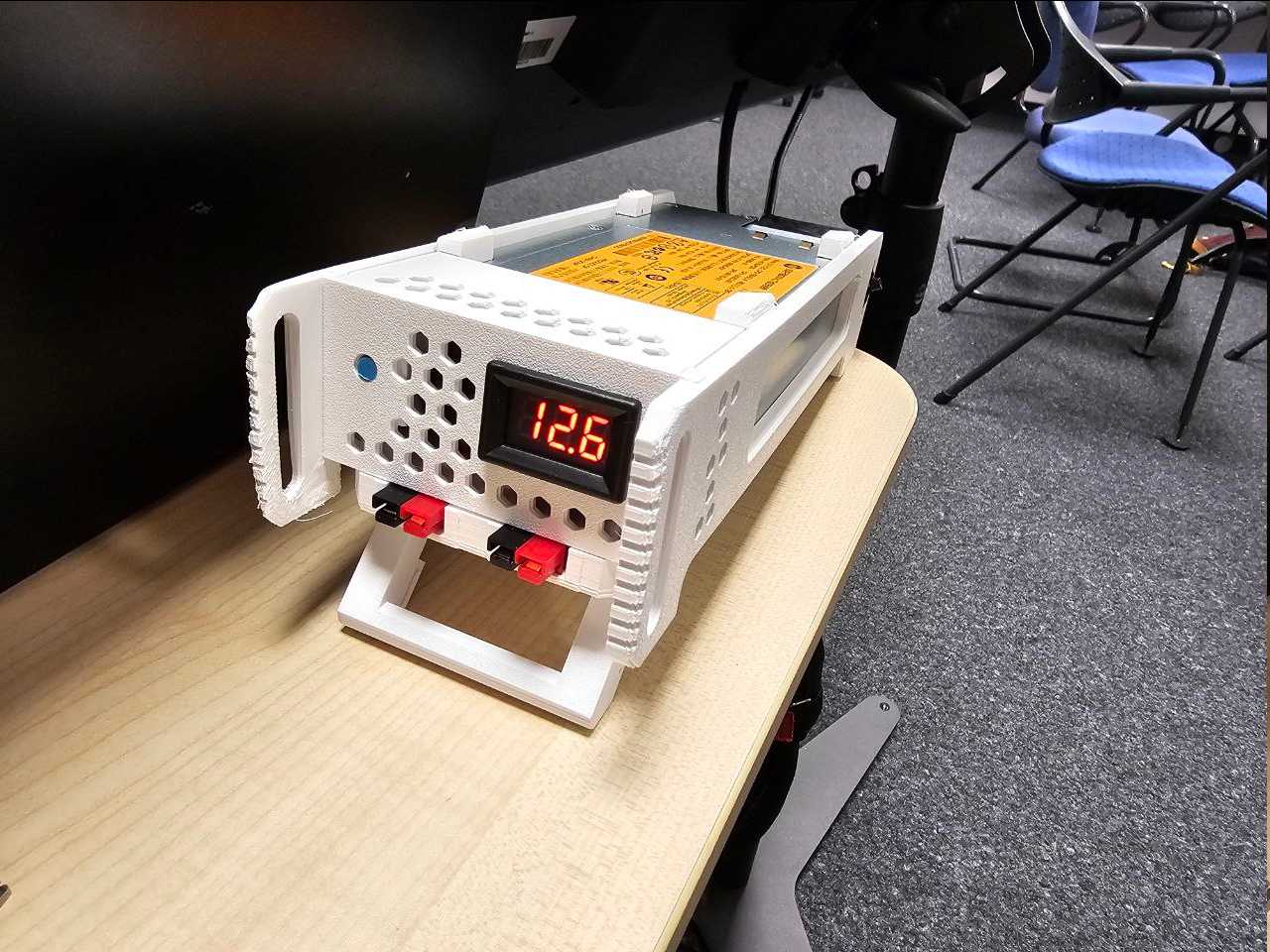

Helge presented a lab power supply capable of delivering 12V, with plans to upgrade it to 13.8V — a common voltage for automotive and amateur radio use. The project hints at future expandability and fine-tuning for specific electronics applications.

From filament management innovations to practical electronics and playful prints, Maker Meetup #167 once again highlighted the diversity and ingenuity of the Aachen maker community. As always, it was a space where curiosity meets creativity — and where shared knowledge sparks new ideas.